floor deck roll forming machine

The production line has the characteristics of low noise, stable transmission, convenient operation and beautiful finished products.

floor deck roll forming machine

The production line has the characteristics of low noise, stable transmission, convenient operation and beautiful finished products.

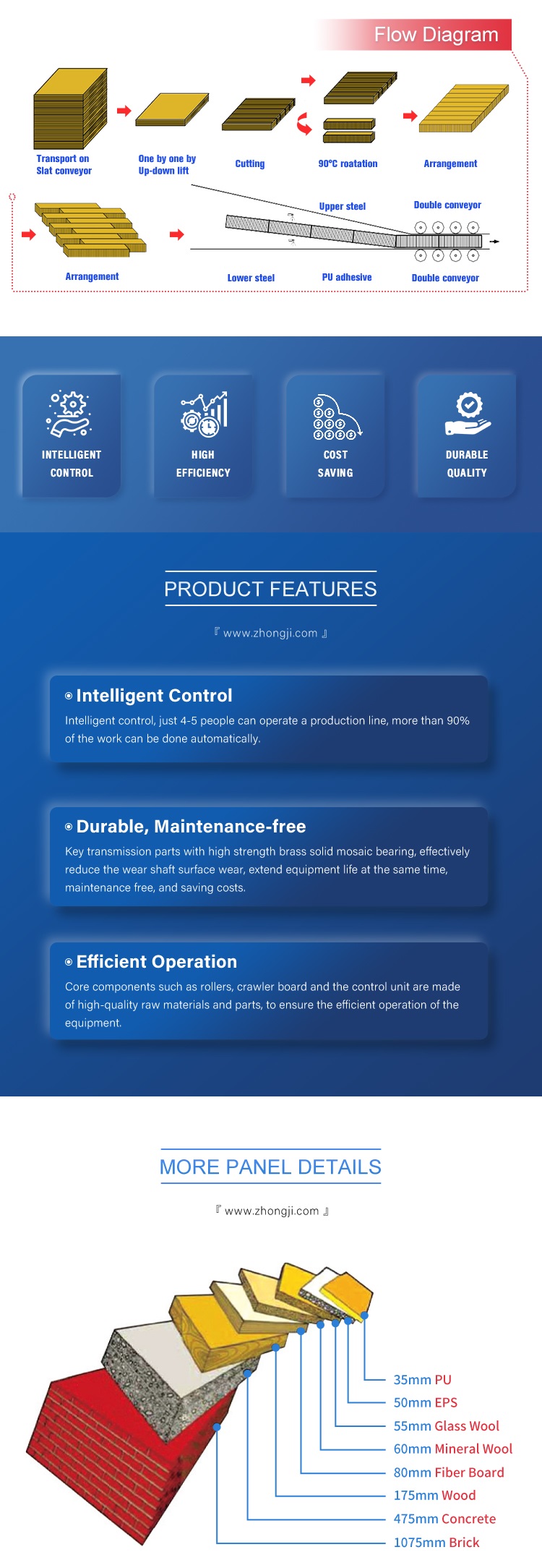

Process flow:

Uncoiling → Guided feeding → Plate lubrication → Roll forming → Cut to length → Finished plate

Main structural form:

1. The uncoiler is composed of a frame and two cone heads. The frame is welded with profiles, steel plates and shot blasted.

2. Hoist the steel coil inside the loading rack, screw in the two cone jacks, press both sides of the coil tightly, and then release the lifting machine.

3. During normal operation, the board is manually introduced into the roller table formed by the main machine, and then the board is passively released with the work of the main machine, and the board is tightened under its own action.

Main feature:

1. This unit is composed of 4T manual feeding device, leveling device, transmission device, forming roller table and main engine (including guiding platform), cutting device after forming, hydraulic system, electric control system, finished product supporting device, etc.

2. Loading and uncoiling (put the steel coil into the inner support type opening frame and tighten it tightly), the two-roller clamp feeds the plate to calibrate and correctly import, level, roll forming, cut after forming, and the finished product is supported and discharged.

Technical parameter:

| parameter | unit |

| structure | wall panel |

| raw materials | Galvanized steel |

| Feed width approx. | 1000 |

| effective width | 760/900 |

| thickness | 0.4-0.6 |

| yield strength | 350 |

| forming speed | 10 |

| forming unit | 14 |

| spindle material | 45# high quality steel, quenched |

| shaft diameter | 75 |

| main motor power | 10 |

| hydraulic station power | 5.5 |

| cutting method | Hydraulic shear, cut off after forming |

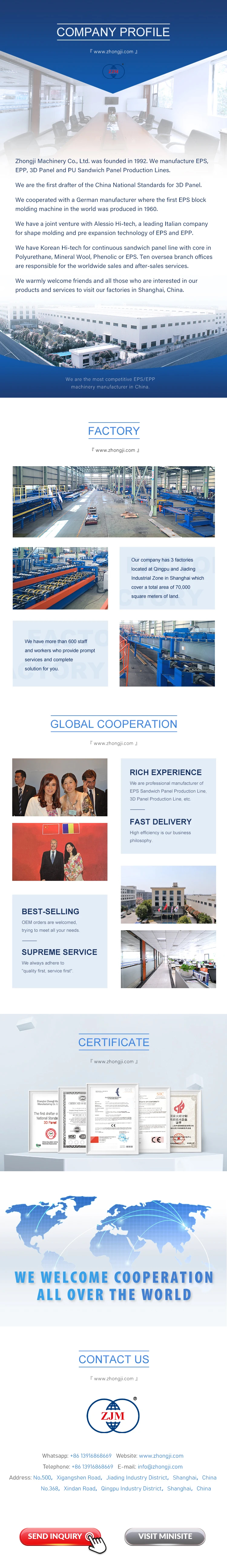

2.The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production line.

(2) Training

Our company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance can not be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 50 items.

Online Message

Reminder: In order to get in touch with you in time, please be sure to fill in your contact information and demand information completely. You can enter your demand, such as the model of the product, testing materials, and the budget range of the product; you can also use your mobile phone Call our account manager.