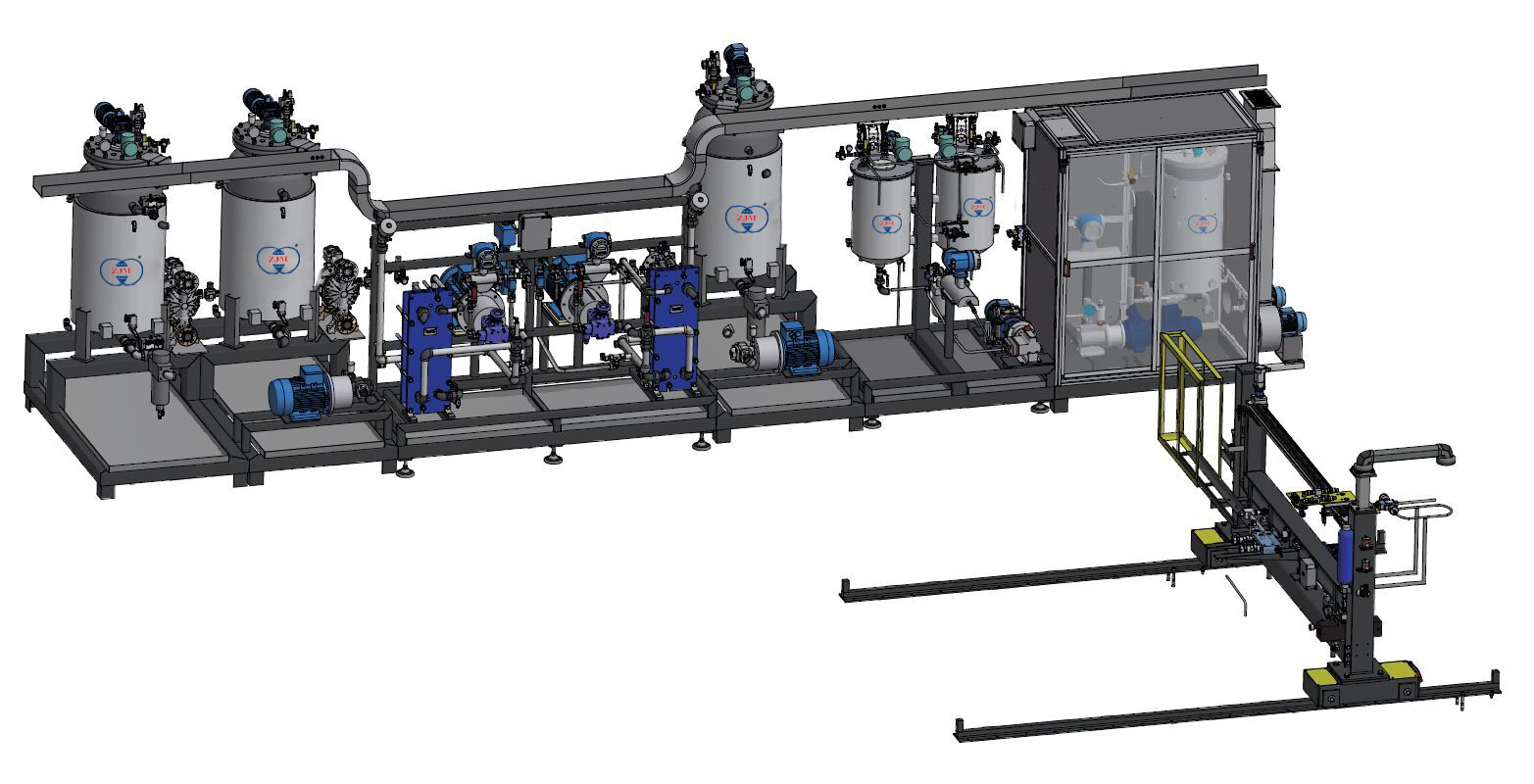

Six-component polyurethane high-pressure foaming machine

The multi-component continuous foaming machine made by our company has the characteristics of accurate measurement, adjustable density, fast speed and self-cleaning function of the gun head. By using self-developed emulsification technology, adding gas mixing device and emulsifying unit, the mixing uniformity and bubble uniformity of feed liquid are greatly improved. Under the same conditions, the density of the sandwich board is lower, the foam hole is more delicate, the thermal conductivity is lower, and the quality is higher.