Double belt conveyor system

The PU foam component mixture applied to the lower facing layer is conveyed in a synchronization motion with the upper facing layer along the double belt for curing.

Double belt conveyor system

The PU foam component mixture applied to the lower facing layer is conveyed in a synchronization motion with the upper facing layer along the double belt for curing.

What is the role of Double Belt Conveyor?

The double belt is designed to contain the uprising pressure during the foam reactive process by the action of a screw jack ensure the required sandwich panel thickness.

The double belt conveyor conveys a continuous panel from PU foaming portal to the cross cutter while containing upper, lower and lateral uprising pressure while keeping up the uniform thickness and steel surface of the finished PU panel.

We make all machines by Korean engineers & Technology

By slat chain guidanTo meet the high standards required for the sandwich panels to be produced, our special technology concerning the design and manufacturing measures of the double belt has been manufactured to the following guidelines.

ce system on the right of the drive wheel, any pitching phenomenon of the slats caused by dropping onto the tooth of the wheel does not occur.

By this technique, any distortion and scratching of the panel surface is avoided and this results

in an utmost uniform panel surface appearance.

The chain guide is made of special steel with a high endurance rating.

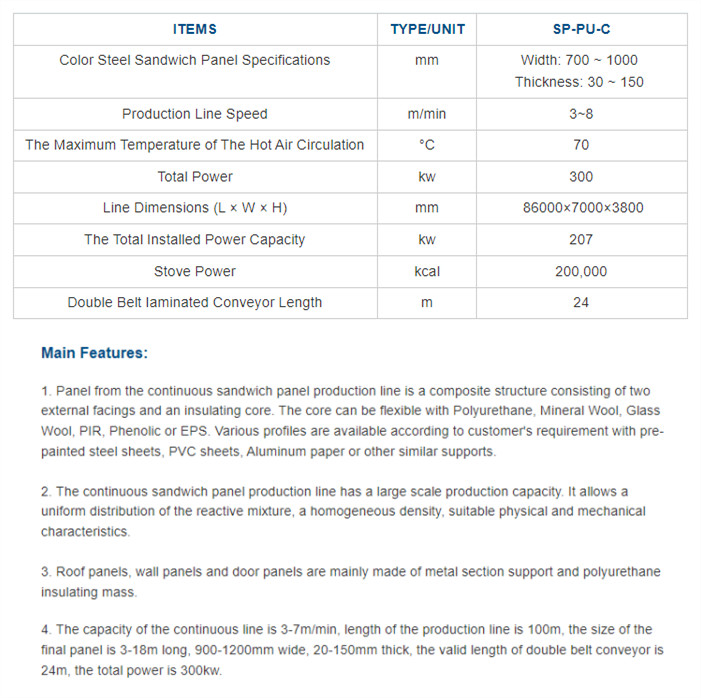

Technical parameter:

| Length of the distance between axles | 24,000mm |

| Working height of lower chain belt | Approx. 1,250mm |

| Slat width | 220mm |

| Slat length | 1,350mm |

| Slat thickness | Approx. 10~12mm |

| Number of slats per chain belt (required during maintenance) |

Max. 300 mm |

| panel thickness | Min. 35~max. 200mm |

| Foaming pressure | Max. 0.5 bar/cm2 |

| Deflection of slats | Max. 0.05mm |

| Lifting time of upper chain belt to max. height | Approx. 1 minutes |

| Power requirement for drive | Approx. 2 × 7.5kw |

| Power requirement for screw jack unit | Approx. 7.5kw |

| Max speed | Max 8m/min |

2.The company has a professional The Adjuster team, 24 hours to provide uninterrupted after-sales service.

(1) Installation and debugging

Equipment arrived at the customer workshop, according to the flat layout of our equipment. We will arrange experienced technicians to install, debug and test-produce the equipment, and make the equipment reach the rated production capacity of the production line.

(2) Training

Our company provides technical training for our customers. The training includes the structure and maintenance of the equipment, the control and operation of the equipment, experienced technicians will guide and establish the training program. After training, the buyer's technical personnel can master the operation and maintenance of the equipment, can adjust the process and deal with different failures.

3.After-sales quality problems within 2 hours to answer, if the telephone video guidance can not be solved, domestic 24 hours to send engineers to the site to solve the problem.

4. Factory direct sales price concessions, 40,000 square meters factory, 20 years of Export Enterprises, CE certification, patents more than 50 items.

Online Message

Reminder: In order to get in touch with you in time, please be sure to fill in your contact information and demand information completely. You can enter your demand, such as the model of the product, testing materials, and the budget range of the product; you can also use your mobile phone Call our account manager.